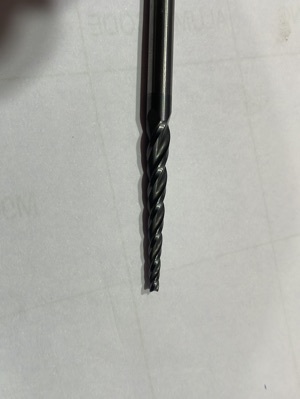

Diamond File

Price 490 -590 INR/ Piece

MOQ : 5 Units

Diamond File Specification

- Type

- Diamond File

- Material

- Industrial Grade Steel with Diamond Coating

- Application

- Precision filing, shaping, and finishing of hard materials such as carbide, glass, ceramics, and hardened metals

- Length

- 150 mm

- Color

- Silver/Black

- Handle Material

- Non-slip Plastic

- Thickness

- 3 mm

- Usage

- Manual filing

- Durability

- High wear resistance and long service life

- Coating Grade

- Fine (220-600 Grit)

- Shape

- Flat

- Width

- 10 mm

- Surface Finish

- Electroplated Diamond

Diamond File Trade Information

- Minimum Order Quantity

- 5 Units

- FOB Port

- Mumbai Port

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Days after Acceptance (DA), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 100 Units Per Week

- Delivery Time

- 2 Days

- Main Export Market(s)

- Australia, Central America, North America, South America, Eastern Europe, Asia

- Main Domestic Market

- All India

About Diamond File

Our organization provides the best quality of Diamond File that is known for its fine finish as it has the capability to work in any direction. It can be used in many fields such as for sharpening the carbide cutting tools, opening up of holes in hardened surfaces, removing of excess solder, fitting clock and watch glasses and many more. Since our Diamond File does not consist of actual teeth rather it consists of diamond grit, therefore it can sharpen and provide a fine finish to the materials in any direction, thus it is the best replacement of traditional steel file as well.

Precision and Performance for Hard Materials

Designed to handle tough materials like carbide, glass, ceramics, and hardened metals, this diamond file delivers precise results every time. The flat profile, combined with electroplated diamond coating, ensures optimum material removal and finishing, making it suitable for demanding professional and industrial applications.

Durable Construction and Comfortable Handling

With a robust industrial-grade steel base and high-quality diamond coating, this file offers exceptional durability and long wear life. The non-slip plastic handle ensures a secure grip, providing comfort and control during extended use. Its fine grit range caters to delicate and accurate finishing work.

FAQs of Diamond File:

Q: How should I use the flat diamond file for precision filing?

A: Begin by securing the workpiece and using smooth, controlled strokes along the surface you wish to file. The fine, electroplated diamond coating is suitable for precise shaping and finishing of hard materials. Always file in one direction for the best results.Q: What materials can this diamond file be used on?

A: This file is designed for hard substances including carbide, glass, ceramics, and hardened metals. Its industrial-grade construction and fine grit make it ideal for detailed shaping and finishing tasks in both professional and industrial environments.Q: When is it appropriate to use a fine grit diamond file like this one?

A: It is best used when you require smooth finishes or delicate shaping, especially during the final stages of material preparation. The 220-600 grit is perfect for detailed refinement and achieving a polished surface on hard materials.Q: Where can this diamond file be utilized?

A: This flat diamond file is suitable for workshops, manufacturing facilities, craftsman studios, and industrial applications. It is well-suited for tasks requiring high precision, including tool maintenance and specialty fabrication work.Q: What is the process for maintaining the diamond coating on the file?

A: After use, clean the file with a soft brush to remove debris and avoid clogging the diamond grit. For stubborn residues, use water and mild detergent, then dry thoroughly. Proper maintenance ensures optimal performance and prolongs service life.Q: What are the main benefits of choosing this particular diamond file?

A: The file offers superior durability, high wear resistance, and reliable performance on hard materials. Its ergonomic, non-slip handle enhances comfort, while the fine diamond coating delivers accurate, smooth results for a range of filing and finishing applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Abrasives Product Category

Carbide Rotary Burr

Price 250.0 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Carbide Rotary Burr

Product Type : Carbide Rotary Burr

Size : Carbide Rotary Burr

Carbide Degree Taper End Mill

Price 2500.0 INR / Piece

Minimum Order Quantity : 5 Pieces

Usage : Milling purpose

Size : 3mm x 3dgree x 45 x 75mm

CARBIDE INSERTS

Price 120.0 INR / Piece

Minimum Order Quantity : 100 Pieces

Usage : CARBIDE INSERTS

Product Type : CARBIDE INSERTS

"We Only Deal In End User"

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS