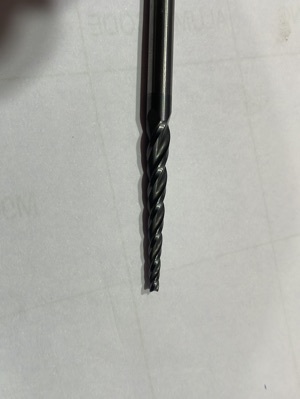

Carbide Rotary Burr

Price 250.0 INR/ Piece

MOQ : 1 Piece

Carbide Rotary Burr Specification

- Usage

- Carbide Rotary Burr

- Type

- Carbide Rotary Burr

- Material

- Tungsten Carbide

- Application

- Grinding, Cutting, Shaping, Deburring Metals

- Size

- Carbide Rotary Burr

- Product Type

- Carbide Rotary Burr

- Surface Finish

- High Precision, Smooth

- Shape

- Cylindrical with End Cut

- Usage

- Industrial, Automotive, Metalworking

- Overall Length

- 65 mm

- Cut Type

- Double Cut

- Compatibility

- Compatible with Die Grinders and Rotary Tools

- Burr Diameter

- 12 mm

- Shank Diameter

- 6 mm

- Hardness

- HRC 90-93

Carbide Rotary Burr Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Mumbai Port

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 4 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Carbide Rotary Burr

With the property of rust-resistive, our Carbide Rotary Burr is ideal for shaping the different materials that will last long without chipping or breaking. The premium quality of stainless steel material used offers optimum performance on the materials. The offered burr is applicable to work with various materials such as a cast iron, wood, acrylics, fiberglass, and plastic. Also, it is suitable for the soft metals such as gold, silver, carbide, and platinum for giving a smooth finish. Apart from this, our Carbide Rotary Burr is available to our clients in varied sizes, with different types of designs.

Precision Cylindrical Burr for Demanding Applications

Engineered for industrial-grade tasks, our cylindrical carbide rotary burr with end cut ensures meticulous results in grinding, shaping, and deburring operations. The double cut design enhances metal removal efficiency while minimizing vibration and producing a smoother surface. Its robust tungsten carbide construction ensures longevity and consistent high-performance.

Versatile Compatibility with Die Grinders and Rotary Tools

Designed to fit standard die grinders and rotary tools, this carbide rotary burr is versatile across a wide range of devices. Its 6 mm shank diameter guarantees secure mounting and stable operation, supporting various workflows in workshops, garages, and factory floors.

FAQs of Carbide Rotary Burr:

Q: How is the cylindrical carbide rotary burr with end cut used in industrial and automotive applications?

A: The carbide rotary burr is attached to die grinders or rotary tools and used for grinding, cutting, shaping, and deburring metal surfaces in manufacturing, repair, or maintenance processes, delivering precise results thanks to its double cut design.Q: What type of materials can this tungsten carbide rotary burr process?

A: This burr is designed to work efficiently on metals, including steel, cast iron, aluminum, and other alloys, making it suitable for a variety of metalworking tasks.Q: When should I choose a double cut carbide burr over other cut types?

A: Double cut carbide burrs are ideal for situations that require faster material removal, finer surface finish, and reduced chip size, especially in industrial and automotive grinding or deburring operations.Q: Where can I source this carbide rotary burr in India?

A: You can obtain this carbide rotary burr from exporters, importers, manufacturers, suppliers, traders, and wholesalers operating throughout India, ensuring broad availability across major industrial centers.Q: What benefits does the high precision, smooth surface finish offer during metalworking?

A: The high precision and smooth finish minimize post-processing requirements, reduce material waste, and increase the quality of finished components, which is valuable in automotive and industrial production.Q: What is the process for installing the burr onto a die grinder or rotary tool?

A: Simply insert the 6 mm shank into the collet of the compatible die grinder or rotary tool, tighten the chuck securely, and verify the fit before operation to ensure optimal safety and performance.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Abrasives Product Category

Carbide Degree Taper End Mill

Price 2500.0 INR / Piece

Minimum Order Quantity : 5 Pieces

Usage : Milling purpose

"We Only Deal In End User"

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free